-

GATE

ACCESS CONTROL

PARKING ACCESS

PARKING GUIDANCE

ACCESSORIES

Welcome to Excelsoo! Contact us. Ph./WhatsApp/WeChat: +86-138-2870-1707

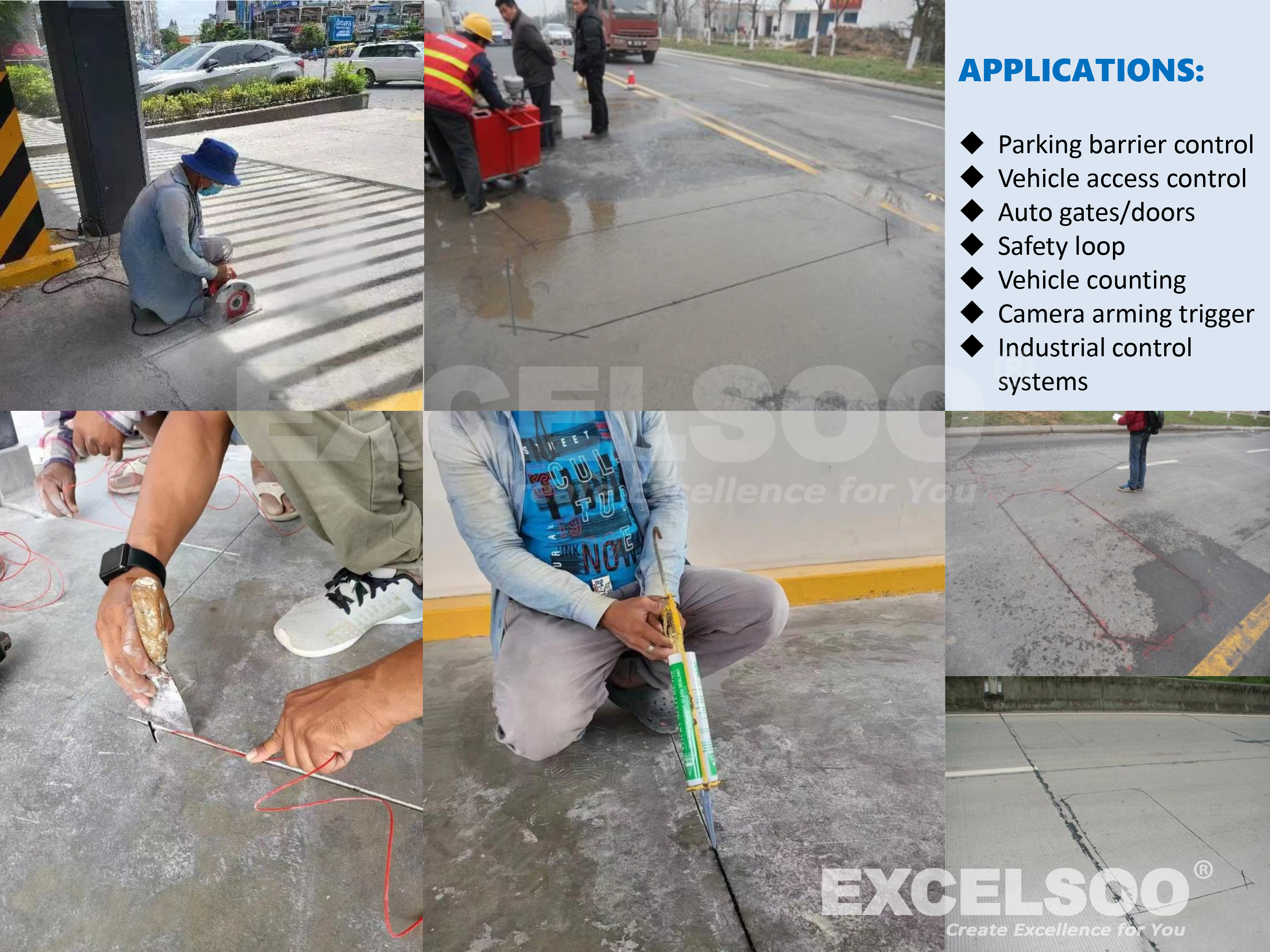

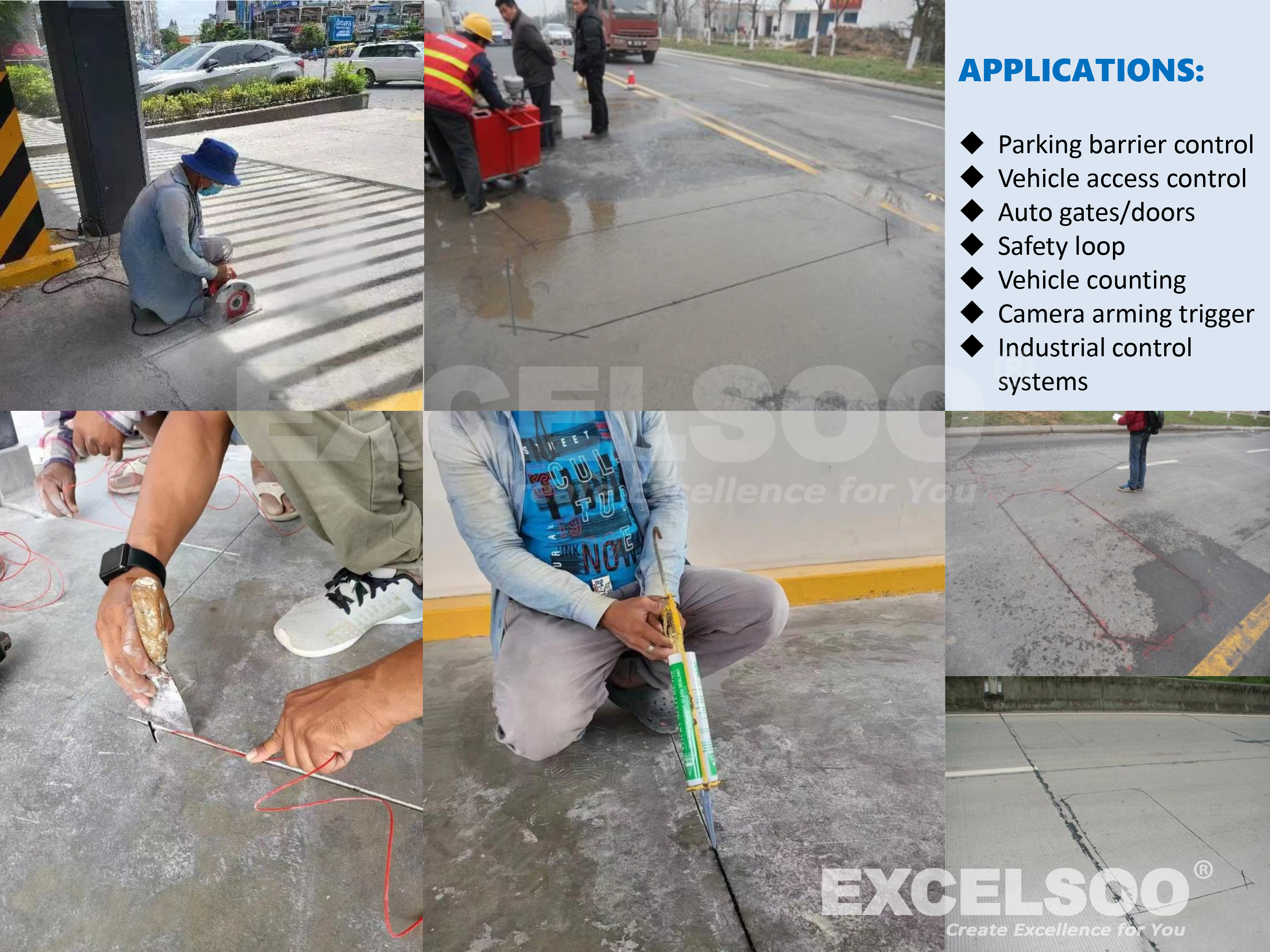

How do you install a loop sensor for boom barrier gate?

- CAUTION

● Pay more attention to power supply voltage avoiding the wrong connection damaging the detector.

● Please read the instructions carefully before usage.

Loop Installation

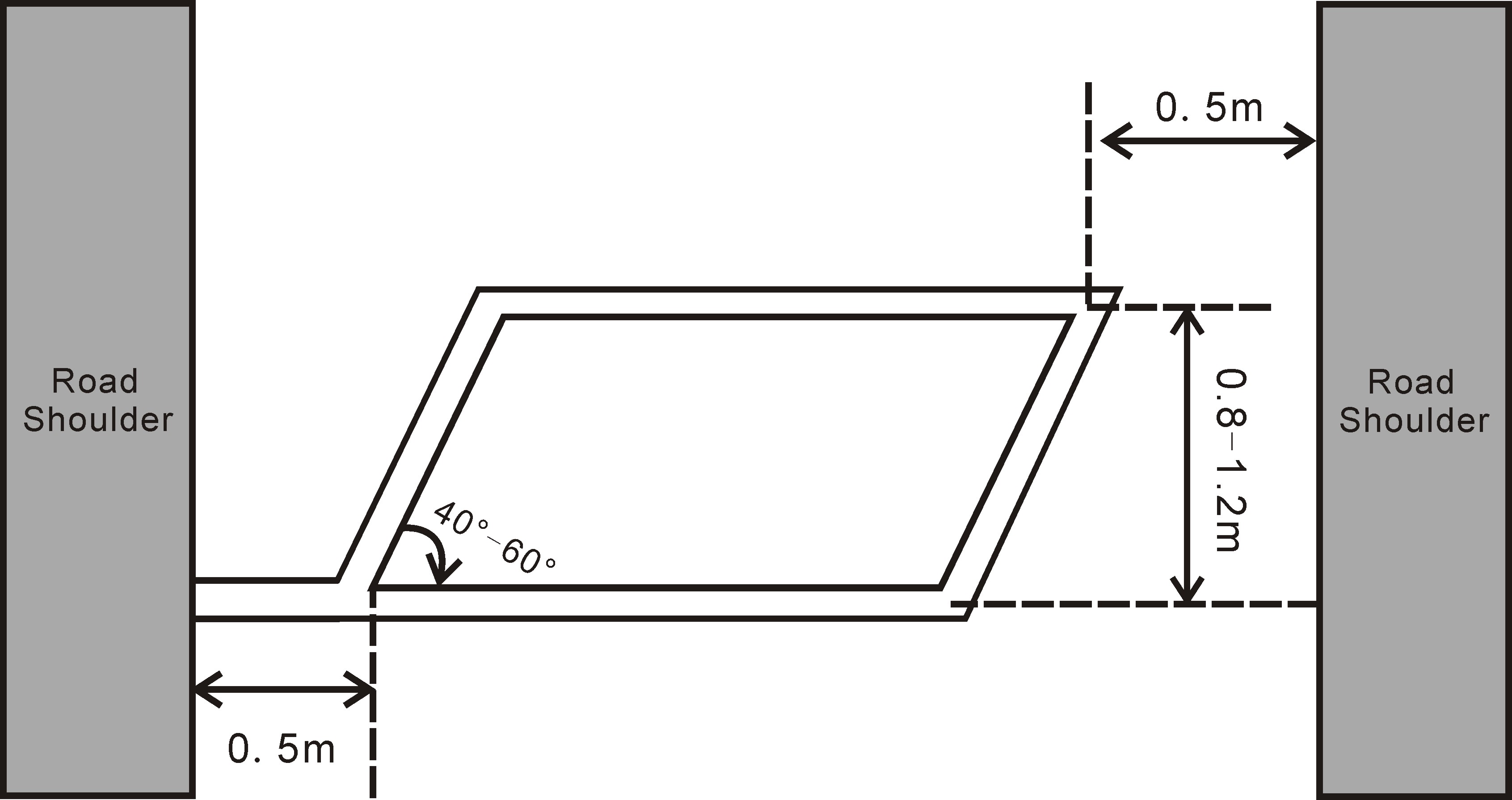

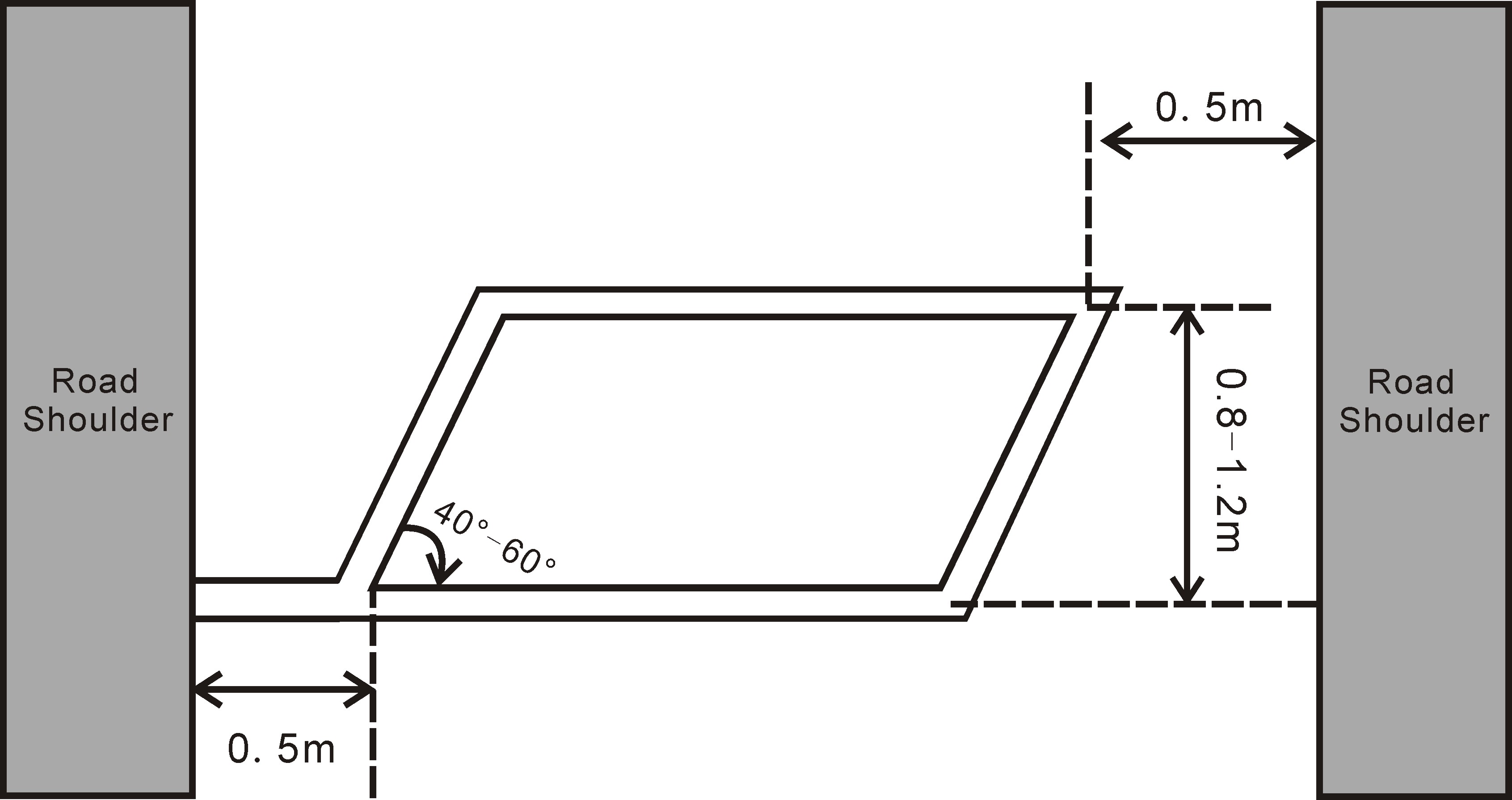

Using a disc cutting machine or the like to cut cable slots, a 45°oblique angle should be made across the loop corners to reduce the chance of damage that can be caused to the loop cable at right angle corners.

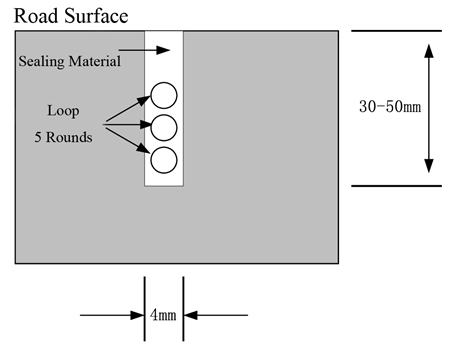

Suggested Width of Slots: 4mm

Suggested Depth of Slots: 30~50mm

A slot must also be cut from the loop circumference at one corner of the loop to the roadway edge to accommodate the feeder.

A continuous loop and feeder are obtained by leaving a tail long enough to reach the detector before inserting the cable into the loop slot.

The loops are sealed using a “quick-set” black epoxy resin or hot bitumen mastic to blend with the roadway surface.

Notes for Installation:

Notes for Installation:

● Crosstalk

When two loops is installed closely, crosstalk will be triggered that one loop magnetic field has interference to another one, which will cause false detection and deadlock. It can be eliminated by the following measures:

- The minimum distance between two loops more than 2M.

- Where feeders are routed together with another electrical wiring, the use of a shielded cable is suggested.

● Other Metal Objects Impacts

There will be impacts caused by other metal objects below the road to loop’s inductance change. So 1~2 turns of loops will be added usually to compensate for inductance.

● Feeder

The cable between the loop and detector is called a feeder. The feeder should be of the same material but twisted, a minimum of 20 twists per meter. It should be noted that the loop sensitivity decreases as the feeder length increases, so ideally, the feeder cable should be kept as short as possible. The maximum recommended loop feeder length is less than 10meter.

● Specification of Loop and Feeder

- The loop and feeder must consist of single multi-strand no joints insulated copper wire with a minimum cross-sectional area equivalent to 0.75 square millimeters.

- Joints in the loop or feeders are not recommended. Where this is not possible, joints are to be soldered and terminated in a waterproof junction box. This is extremely important for reliable detector performance.

- The length of the loop will be determined by the width of the roadway to be monitored. In general, the length of the loop cable is between 30m~50m.

FAQ

SUPPORT

LINK:

Follow Us:

Ph./WhatsApp/WeChat:

QUICK LINKS

HOW CAN WE HELP YOU?

SUPPORT

Follow Us on

WeChat: